Jochen G?th, Performance Consultant at Fette Compacting, remembers his last customer visit in Africa: “Actually I was only there to optimize the production of an anti-malaria product on a new FE75 tablet press.” But since he was in any case already on site, the Performance Consultant also took on the optimization of another machine. In the process of modernizing the production facility, the customer wanted to transfer the manufacture of a double-layer tablet to the FE75. It was therefore only logical to take a look at the existing parameters and settings.

Special features of double-layer tablets

Double-layer tablets are most often used when two active ingredients cannot be brought together in one mixture. This can be the case, for example, if the actual medication should have a stomach-protecting agent added, or when a delayed release of active ingredient is needed. The machine was fitted out in advance for this purpose, using two filling stations for the double-layer production. In addition, the first part of the tablet has received initial pressing before it is combined with the second component to make a sturdy double-layer tablet.

A question of timing

“The timing and the control rate of the pressing force are central control parameters that affect the properties of the tablet and of the entire process at various locations,” explaines G?th. In the case of the double-layer tablet, a whole range of settings were less than optimum on the original machine (3090i). “It started with the outlet deflector delay which was set to a very high figure of ten seconds. It went on with the lead time of the Fill-O-Matic, which was five seconds, and a run-on time of ten seconds, which are not required for normal applications. The control lag was also not properly chosen. This can be used to set when the machine attempts to adjust to achieve the optimum pressing force,” continues G?th.

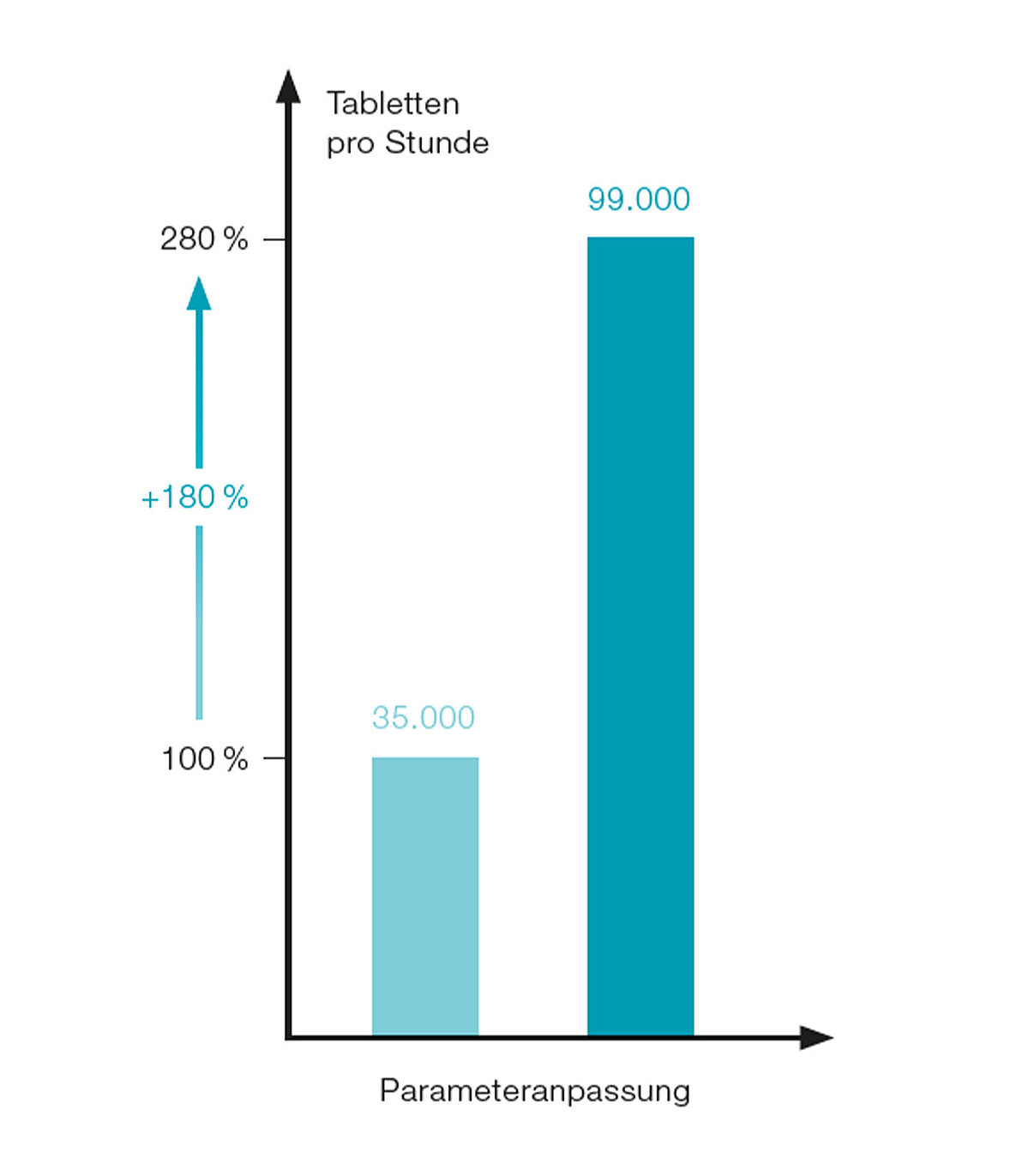

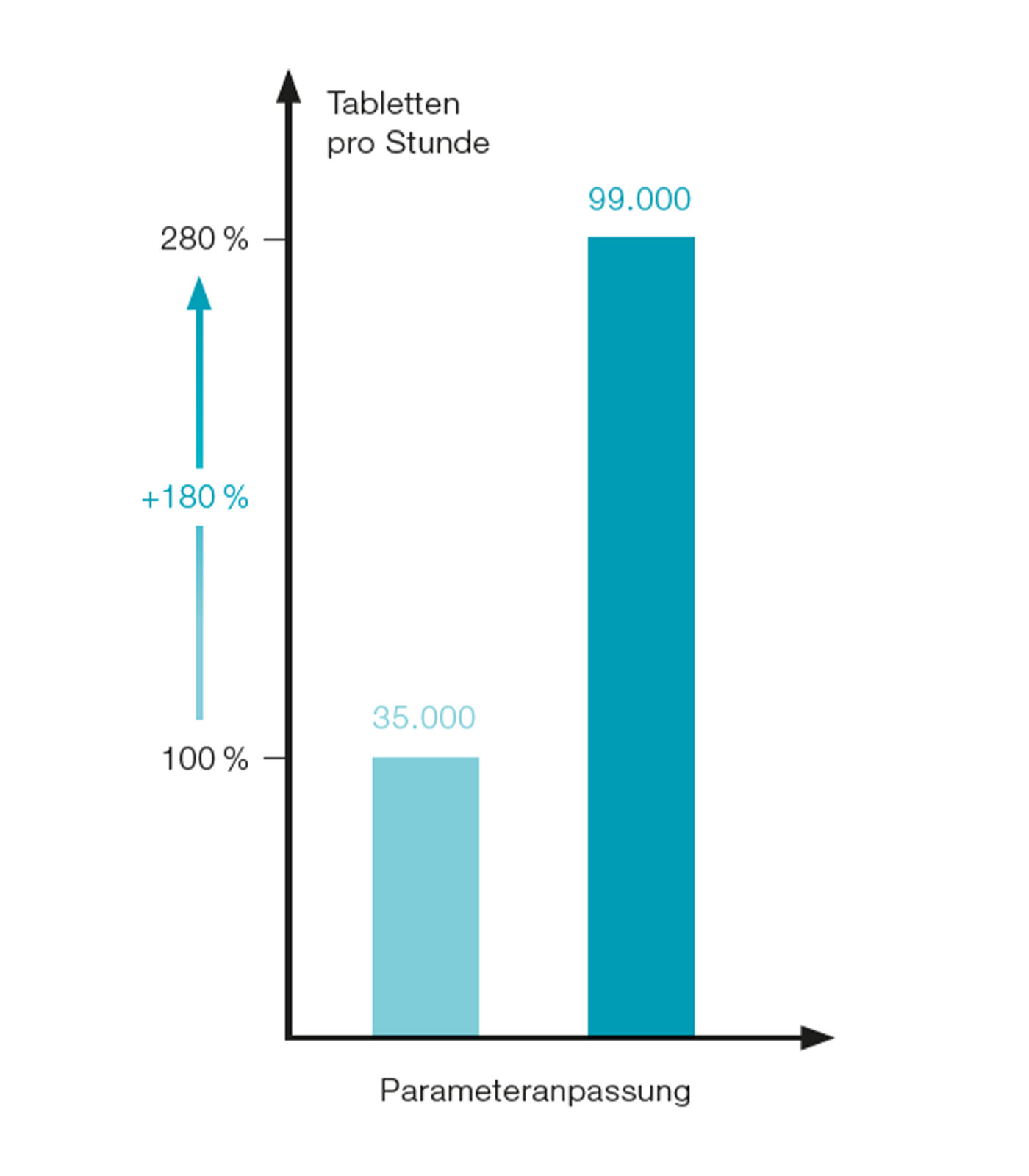

All the values were first set to zero in order to find out which parameters were not optimum. It became clear that the control lag above all was critical for the process flow. The machine had made adjustments too soon and they were too much. An adjustment to the delay is often a central lever for optimizing a machine. After changing to a control lag of ten seconds, the process ran smoothly. The parameter adjustment alone achieved an increase of 17 percent in the output (from 35,000 to 41,000 tablets per hour).

From 35,000 to 99,000 tablets each hour

The experience gained on the 3090i provided a good basis for optimizing the process again on the FE75. The filling unit is responsible for filling the segment holes, and it was changing this that made the crucial difference. G?th suggested that the filling cone system, available particularly on the FE Series, should be used. Depending on the tablet size, the flow rate of the material and the production speed, this brings about better filling properties, and has proven itself particularly useful for large tablets.

In this way it was possible to increase the output from 35,000 tablets per hour to 99,000 tablets per hour, without losing any quality. G?th’s summary of potential optimization was that, “A 180 percent increase in output is nothing rare. The fact is that if appropriate parameters or settings are not optimum, this often has fundamental effects.”

Tablet presses from Fette Compacting are aimed precisely at the needs of modern medication production, and offer the highest possible reliability and performance. The potential can be increased even further with the help of Performance Consultants. Their expertise provides more efficient production, increases the value creation, and allows the processes to be optimized continuously.